f83200557c640a8839366d6b622d3b9c68ac78b7

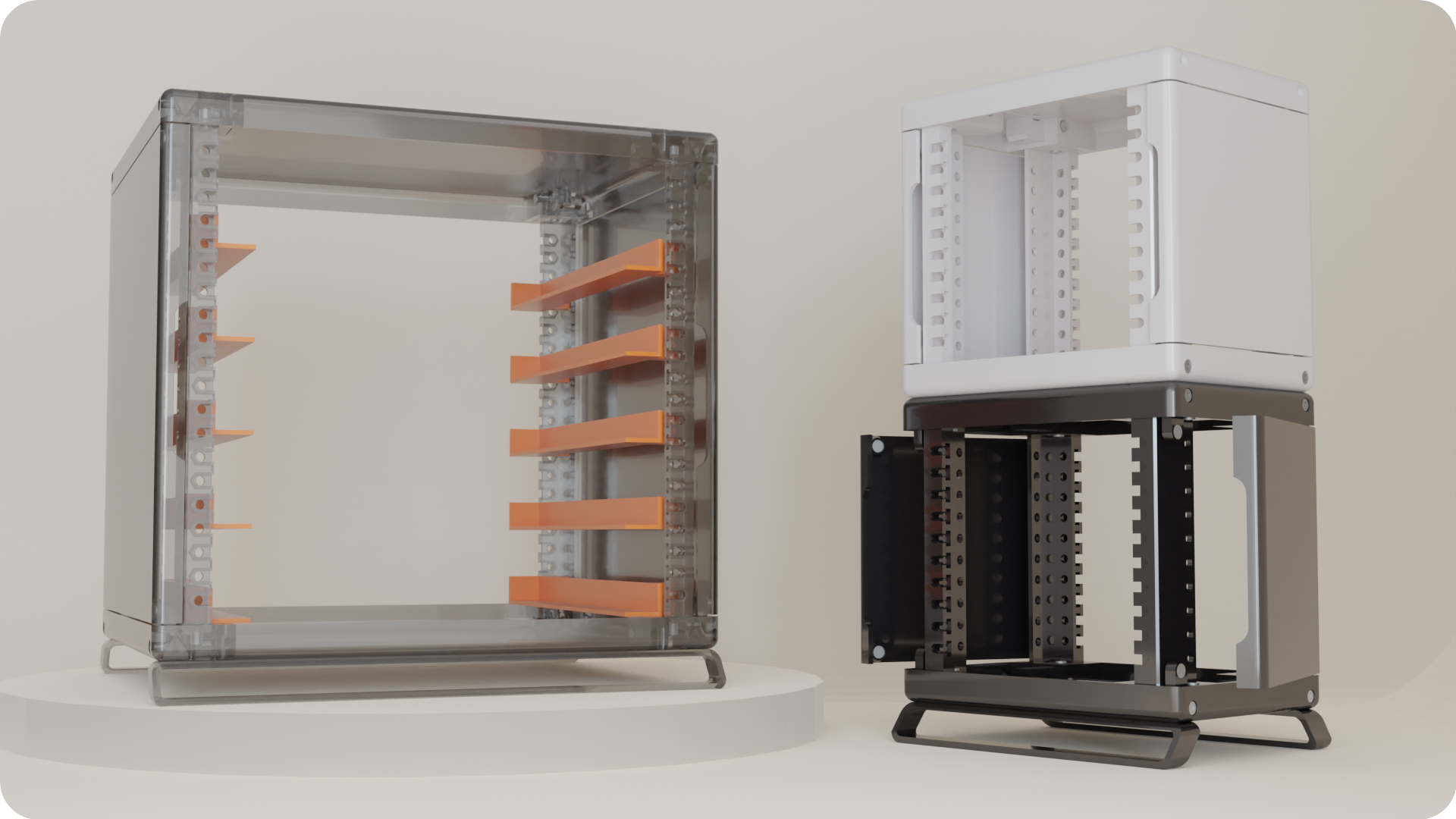

rackstack

A parametric 3d-printable mini rack system

- Mount Anything: Perfect for organizing SBCs, mini PCs, small switches, power hubs, etc.

- Fully customizable: Fully written in OpenSCAD. Everything, from the dimensions of the rack, to the roundness of the corners, can be modified with a simple code change.

- Printable from home: Designed to be printed with conventional FDM printers. Requires minimal supports when printing, and final assembly needs only a few easy-to-source parts.

- No cage nuts! Sliding hex nut design for the front rails allows one to easily mount items without dealing with cage nuts.

- Stackable: Individual racks can be easily stacked and fastened together. Mix and match different color and design combinations!

Renders

See the renders for difference parametric profiles here

Assembly

Pre-generated STLs for roughly 200mm^3, and 100mm^3 rack frames can be found in stl/rack.

These STLs are generated from the files in rack/print, and rack-mount/print - further information about printing these parts

(supports, orientation) can be found in their respective .scad files.

Assembly Instructions

Please see the assembly README here

Required Tools:

- 3d FDM Printer - build size requirements depend on configure rack size. (TODO explain)

- M3 Allen Key

- M4 Allen Key

BOM - Single Rack:

Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS), but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x10 FHCS (TODO confirm)

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws

Configuring + Generating STLs

WIP

Requirements:

openscadcli command (Only runs on Linux)python3

python3 rbuild.py --help

Languages

OpenSCAD

92.7%

Python

6.7%

Shell

0.6%