4.9 KiB

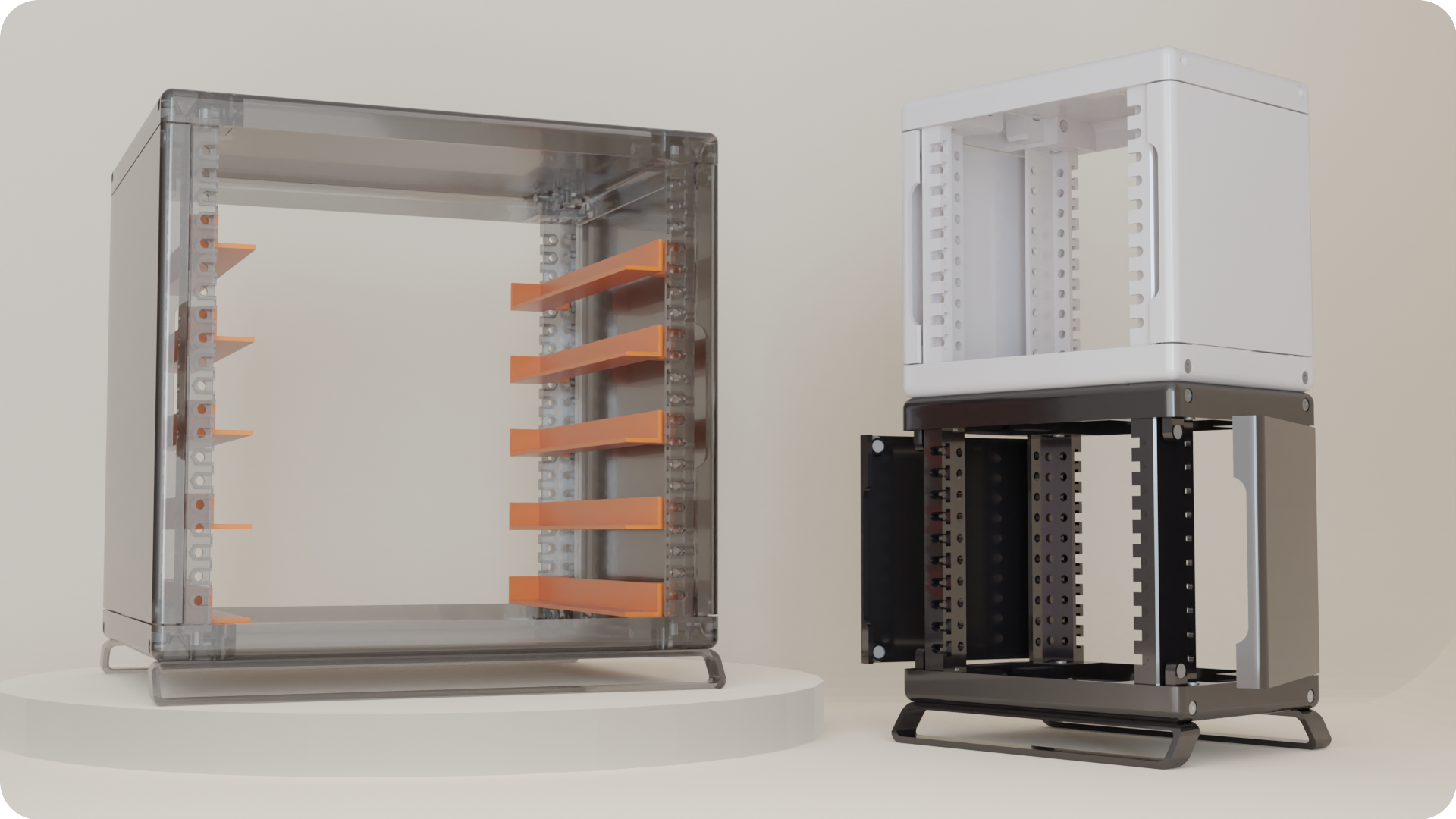

rackstack

A parametric 3d-printable mini rack system

- Mount Anything: Perfect for organizing SBCs, mini PCs, small switches, power hubs, etc.

- Fully customizable: Fully written in OpenSCAD. Everything, from the dimensions of the rack, to the roundness of the corners, can be modified with a simple code change.

- Printable from home: Designed to be printed with conventional FDM printers. Requires minimal supports when printing, and final assembly needs only a few easy-to-source parts.

- No cage nuts! Sliding hex nut design for the front rails allows one to easily mount items without dealing with cage nuts.

- Stackable: Individual racks can be easily stacked and fastened together. Mix and match different color and design combinations!

Renders

See the renders for difference parametric profiles here

Assembly

Pre-generated STLs for roughly 200mm^3 (mini), 180mm^3 (micro), and 100mm^3 (nano) rack frames can be found in stl. These STLs are generated from the files in rack/print, and rack-mount/print - further information about printing these parts (supports, orientation) can be found in these files.

Assembly Instructions

Please see the assembly README here

Required Tools:

- 3d FDM Printer - build size requirements depend on configured rack profile

- M3 Allen Key (for constructing the rack)

- M4 Allen Key (for mounting rack-mount items)

BOM - Single Rack:

Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS), but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x12 FHCS.

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws.

Configuring + Generating STLs

A python script: rbuild.py is provided to generate different project stls.

Requirements:

openscadcli command (Only runs on Linux)python3

Examples:

Generate all project files for the micro profile:

python3 rbuild.py -b all --nightly -c micro

This will build all the required STLs for a micro rack in the stl/custom/ directory. The --nightly is optional and

means the build script will use the openscad-nightly command, instead of openscad. This usually results in much

faster build times and is generally recommended.

For generating a specific part:

python3 rbuild.py -b yBar --nightly -c micro -t custom

Generated stls are put into the stl/ directories. The actual variable values for different profiles can be found in

rack/profiles.scad.

We recommend you start by printing the eval_P.stl file first, just to determine if the default slack/layer height

configurations work for you. If parts are too tight/loose please take a look at

config/slack.scad. Please also adjust config/printing.scad to match your

slicer settings.