# rackstack

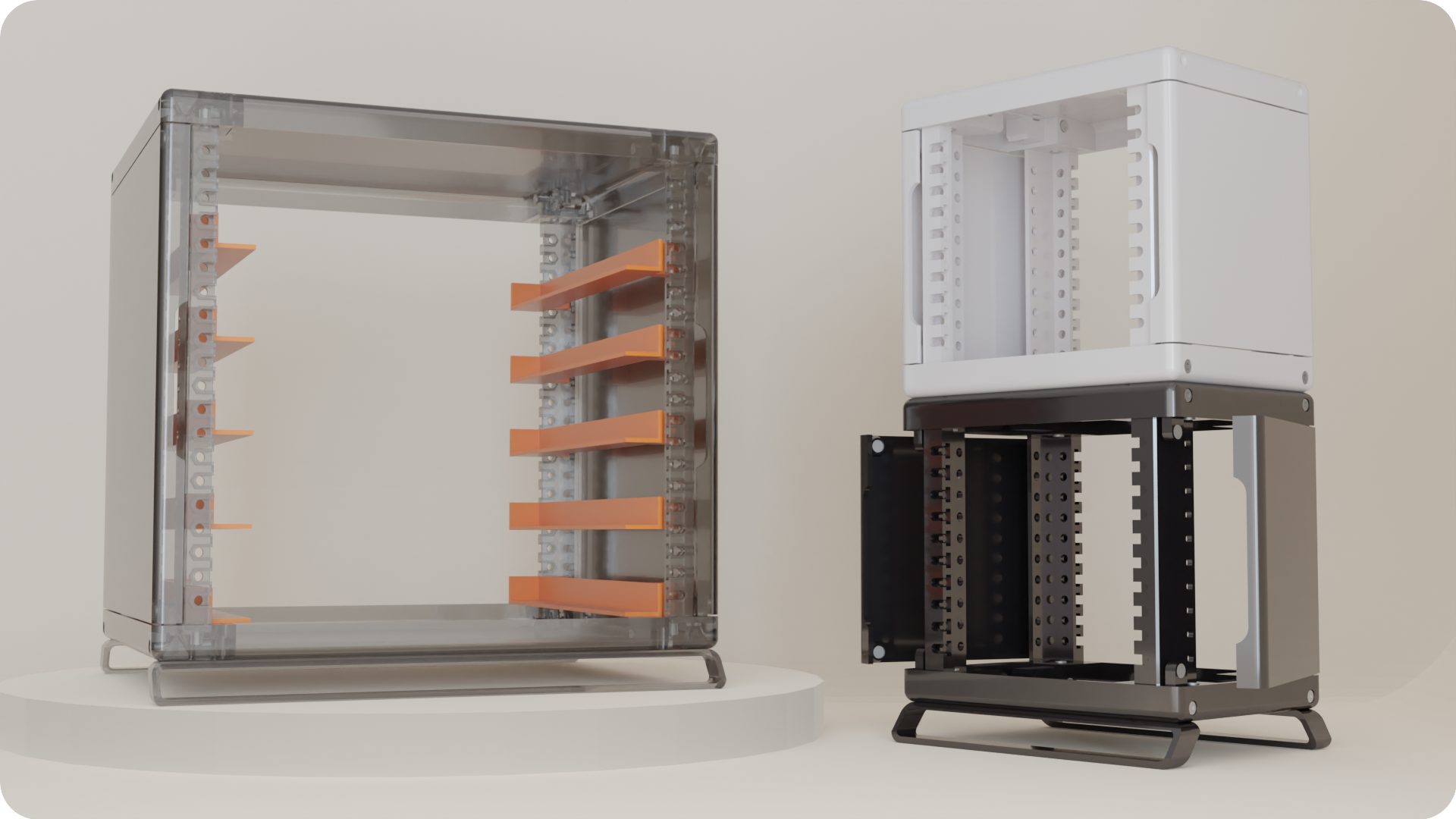

### A parametric 3d-printable mini rack system

- ***Mount Anything:*** Perfect for organizing SBCs, mini PCs, small switches, power hubs, etc.

- ***Fully customizable:*** Fully written in OpenSCAD. Everything, from the dimensions of the rack, to the roundness of the corners, can be modified with a simple code change.

- ***Printable from home:*** Designed to be printed with conventional FDM printers. Requires minimal supports when printing, and final assembly needs only a few easy-to-source parts.

- ***No cage nuts!*** Sliding hex nut design for the front rails allows one to easily mount items without dealing with cage nuts.

- ***Stackable:*** Individual racks can be easily stacked and fastened together. Mix and match different color and design combinations!

### Renders

See the [renders for difference parametric profiles here](media/renders)

## Assembly

Pre-generated STLs for roughly 200mm^3 (mini), 180mm^3 (micro), and 100mm^3 (nano) rack frames can be found in [stl](stl).

These STLs are generated from the files in [rack/print](rack/print), and [rack-mount/print](rack-mount/print) - further information about printing these parts

(supports, orientation) can be found in these files.

### Assembly Instructions

Please see [the assembly README here](./assembly-guide)

### Required Tools:

- 3d FDM Printer - build size requirements depend on configured rack profile

- M3 Allen Key (for constructing the rack)

- M4 Allen Key (for mounting rack-mount items)

### BOM - Single Rack:

| Item | Name | Quantity | Comment |

|---------------------------------------------------------------|---------------------------|----------|----------------------------------------------------------------------------------------------------------------------------------|

|  | M3x12 FHCS | 20 | Extras are useful and inexpensive. If you plan on eventually stacking multiple racks together, don't hesitate to get a lot more. |

|

| M3x12 FHCS | 20 | Extras are useful and inexpensive. If you plan on eventually stacking multiple racks together, don't hesitate to get a lot more. |

|  | M3x16 FHCS | 16 | ☝️ |

|

| M3x16 FHCS | 16 | ☝️ |

|  | M3 hex nut | 36 | ☝️ |

|

| M3 hex nut | 36 | ☝️ |

|  | 3x10 steel dowel pin | 4 | 3mm diameter, 10mm height |

|

| 3x10 steel dowel pin | 4 | 3mm diameter, 10mm height |

|  | 6x2 neodymium disc magnet | 8 | 6mm diameter, 2mm height |

|

| 6x2 neodymium disc magnet | 8 | 6mm diameter, 2mm height |

|  | super glue | \>= 2ml | Used to glue magnets to plastic |

#### Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS),

but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x12 FHCS.

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws.

## Configuring + Generating STLs

A python script: `rbuild.py` is provided to generate different project stls.

Requirements:

- `openscad` cli command (Only runs on Linux)

- `python3`

### Examples:

Generate all project files for the `micro` profile:

`python3 rbuild.py -b all --nightly -c micro`

This will build all the required STLs for a micro rack in the `stl/custom/` directory. The `--nightly` is optional and

means the build script will use the `openscad-nightly` command, instead of `openscad`. This usually results in much

faster build times and is generally recommended.

For generating a specific part:

`python3 rbuild.py -b yBar --nightly -c micro -t custom`

Generated stls are put into the `stl/` directories. The actual variable values for different profiles can be found in

[rack/profiles.scad](rack/profiles.scad).

| super glue | \>= 2ml | Used to glue magnets to plastic |

#### Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS),

but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x12 FHCS.

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws.

## Configuring + Generating STLs

A python script: `rbuild.py` is provided to generate different project stls.

Requirements:

- `openscad` cli command (Only runs on Linux)

- `python3`

### Examples:

Generate all project files for the `micro` profile:

`python3 rbuild.py -b all --nightly -c micro`

This will build all the required STLs for a micro rack in the `stl/custom/` directory. The `--nightly` is optional and

means the build script will use the `openscad-nightly` command, instead of `openscad`. This usually results in much

faster build times and is generally recommended.

For generating a specific part:

`python3 rbuild.py -b yBar --nightly -c micro -t custom`

Generated stls are put into the `stl/` directories. The actual variable values for different profiles can be found in

[rack/profiles.scad](rack/profiles.scad). | M3x12 FHCS | 20 | Extras are useful and inexpensive. If you plan on eventually stacking multiple racks together, don't hesitate to get a lot more. |

|

| M3x12 FHCS | 20 | Extras are useful and inexpensive. If you plan on eventually stacking multiple racks together, don't hesitate to get a lot more. |

|  | M3x16 FHCS | 16 | ☝️ |

|

| M3x16 FHCS | 16 | ☝️ |

|  | M3 hex nut | 36 | ☝️ |

|

| M3 hex nut | 36 | ☝️ |

|  | 3x10 steel dowel pin | 4 | 3mm diameter, 10mm height |

|

| 3x10 steel dowel pin | 4 | 3mm diameter, 10mm height |

|  | 6x2 neodymium disc magnet | 8 | 6mm diameter, 2mm height |

|

| 6x2 neodymium disc magnet | 8 | 6mm diameter, 2mm height |

|  | super glue | \>= 2ml | Used to glue magnets to plastic |

#### Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS),

but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x12 FHCS.

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws.

## Configuring + Generating STLs

A python script: `rbuild.py` is provided to generate different project stls.

Requirements:

- `openscad` cli command (Only runs on Linux)

- `python3`

### Examples:

Generate all project files for the `micro` profile:

`python3 rbuild.py -b all --nightly -c micro`

This will build all the required STLs for a micro rack in the `stl/custom/` directory. The `--nightly` is optional and

means the build script will use the `openscad-nightly` command, instead of `openscad`. This usually results in much

faster build times and is generally recommended.

For generating a specific part:

`python3 rbuild.py -b yBar --nightly -c micro -t custom`

Generated stls are put into the `stl/` directories. The actual variable values for different profiles can be found in

[rack/profiles.scad](rack/profiles.scad).

| super glue | \>= 2ml | Used to glue magnets to plastic |

#### Notes:

- Omitted actual plastic for printing. Any conventional 3d printing plastic should do (PLA, PETG, ABS),

but beware of PLA's thermal limits. Higher infill is recommended for all parts.

- For joining two racks, you will need 8 M3 hex nuts, and 8 M3x12 FHCS.

- Main front rails use M4 hex nuts and screws.

- Side rails are mounted using M3 hex nuts and screws.

## Configuring + Generating STLs

A python script: `rbuild.py` is provided to generate different project stls.

Requirements:

- `openscad` cli command (Only runs on Linux)

- `python3`

### Examples:

Generate all project files for the `micro` profile:

`python3 rbuild.py -b all --nightly -c micro`

This will build all the required STLs for a micro rack in the `stl/custom/` directory. The `--nightly` is optional and

means the build script will use the `openscad-nightly` command, instead of `openscad`. This usually results in much

faster build times and is generally recommended.

For generating a specific part:

`python3 rbuild.py -b yBar --nightly -c micro -t custom`

Generated stls are put into the `stl/` directories. The actual variable values for different profiles can be found in

[rack/profiles.scad](rack/profiles.scad).